Macroscopic (MACRO) Examination

General

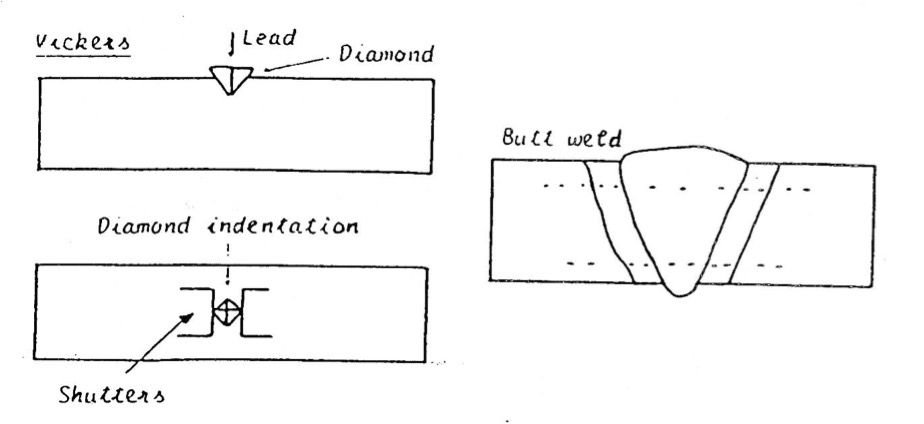

The term macroscopic examination, in this context, refers to the viewing of a polished weld cross-section using a low powered lens – typically x5 magnification – for the purpose of detecting and assessing weld defects, or for the purpose of measuring the actual size of defects already detected. Macro examination of welds is carried out on full thickness specimens which include cap and root. The width of the cross-section should include the heat affected zone plus some parent material. The same test piece is sometimes used for hardness testing after macro examination.

Test procedure

Test specimens are usually cut transversely from a weld. Each test specimen is then ground, polished and etched to the degree required by specification, e.g. for ferritic steels – P400 grade finish with an acid etch using 10-15% nital (nitric acid + alcohol).

After etching, the test specimen is examined visually. The intent is to disclose any cracks, lack of fusion, porosity, slag, etc.

MICROSCOPIC (MICRO) EXAMINATION

The term microscopic examination, in this context, refers to the viewing of a polished weld cross-section using a microscope at high magnification, e.g. 100x or 1000x, usually for the purpose of grain structure analysis, although microscopic defects could also be detected and assessed. This test is primarily used by metallurgists.

The degree of preparation will be much higher than that required for macroscopic examinations, e.g. for ferritic steel: P2100 grade finish followed by 1 µm polish using a diamond paste then an etch using 1- 5% nital.